- HOME

- CONSISTOMETER

- ETCHING SYSTEM

- FLUID BED DRYER

- LOSS ON DRYING

- OXYGEN HEAD SPACE

- PARTICLE REDUCTION

- PARTICLE SIZE & SHAPE

- SAMPLE CONTAINERS STAINLESS STEEL

- SAMPLE DIVIDERS

- SAMPLERS ACCESSORIES

- SAMPLERS LIQUIDS

- SAMPLERS POWDERS

- SIEVE ACCESSORIES

- SIEVE CALIBRATION

- SIEVE CALIBRATION BEADS

- SIEVE CALIBRATOR

- SIEVE SHAKERS

- SIEVES ASTM ISO

- SIEVING SONIC

- SURFACE TENSION

- SINAR MOISTURE PROBE

- WATER ACTIVITY

www.qclabequipment.com

CUSTOMER SERVICE * SALES * TECHNICAL SUPPORT

DELIVERIES WORLDWIDE

PERFORMANCE GUARANTEE

Telephone (804) 318-3686 Toll Free US (866) 244 1578 Fax (703) 991-7133 Hours 8 AM - 6 PM EST INTERNATIONAL & DOMESTIC SALES

-

AGGREGATE SIZING

AGGREGATE SIZING

-

SIEVER VACUUM

SIEVER VACUUM

-

BALANCES

BALANCES

-

BRIX METERS

BRIX METERS

-

SINAR TECHNOLOGY

SINAR TECHNOLOGY

-

COLOR SHADE ANALYSIS

COLOR SHADE ANALYSIS

-

COLOR SHADE ANALYZER

COLOR SHADE ANALYZER

-

COLOR SHADE INLINE

COLOR SHADE INLINE

-

CONSISTENCY METHOD

CONSISTENCY METHOD

-

SAMPLE CONTAINERS

SAMPLE CONTAINERS

-

PARTICLE SIZE INLINE

PARTICLE SIZE INLINE

-

HOMOGENIZERS

HOMOGENIZERS

-

GERMINATION TESTING

GERMINATION TESTING

-

GRAVEL SAND PARTICLE SIZE

GRAVEL SAND PARTICLE SIZE

-

MOISTURE AGRICULTURE

MOISTURE AGRICULTURE

-

MOISTURE INLINE CONTACT

MOISTURE INLINE CONTACT

-

OVEN ALTERNATIVES

OVEN ALTERNATIVES

-

MOISTURE KARL FISCHER

MOISTURE KARL FISCHER

-

MOISTURE DETERMINATION

MOISTURE DETERMINATION

-

OVENS

OVENS

-

PROTEIN AGGREGATES

PROTEIN AGGREGATES

-

RICE LAB

RICE LAB

-

SAMPLE BLENDERS

SAMPLE BLENDERS

-

SAMPLERS

SAMPLERS

-

SEED COUNTER

SEED COUNTER

-

SIEVING SOFTWARE

SIEVING SOFTWARE

-

TABLET MAKING MACHINE

TABLET MAKING MACHINE

-

VISCOSITY

VISCOSITY

EQUIPMENT FOR QUALITY CONTROL AND R&D L3P SONIC SIFTER (FOR PHYSICAL PARTICLE SEPARATIONS)

STORE SEARCH QUICK QUOTE

COMPLETE INTERACTIVE SAMPLER CATALOGUE PDF DOWNLOAD

The original Model L3P Sonic Sifter Separator operates by using sonic pulses combined with mechanical agitation, to provide effective separation of particles in size ranges otherwise unattainable. If you are trying to accomplish non destructive separation of small particles and /or small samples, the L3P is a requirement. Vacuum sievers aren't designed for fines retention, and standard sieve shakers aren't designed for separations below ASTM E 11 Wire Mesh Aperture Sizes. NEW! Advanced Varisifter with universal power supply, adjustable frequency, and horizontal tapping.

Touchscreen Operation

Contact Us

We will get back to you as soon as possible

Please try again later

Using specially designed 3.5 inch (75mm) diameter precision micro-plate sieves, and a patented oscillating air column, the L3P achieves dry, fine particle separations down to 3 microns, with a tolerance of +/- 2 microns. (ASTM E 161) Tighter tolerances are attainable with ultra series electro-formed sieves or custom geometry apertures.

The oscillating air column causes no screen wear or particle attrition, and facilitates endpoint separations in 90% less time, than with standard shaking methods.Practical separation of particles can be accomplished quickly - in less that 10 seconds under favorable conditions,

(Materials with high moisture content, or that agglomerate easily, may not be suitable for use with a sonic sifter. Call if you are unsure.)

Because the sieves are only three inches in diameter, a 10 gram maximum sample size is recommended. (For very small particle separations, 2 grams or a maximum 4cc by volume sample is recommended) Larger particles should also be separated out first. Not recommended for cohesive powders.

ATM L3P Sonic Sifter 610 L3P

HOW IT WORKS

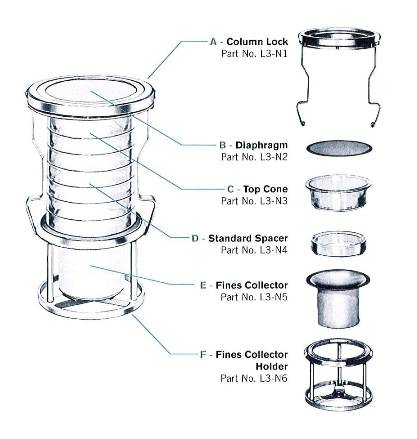

A low frequency audio signal is generated by a large speaker in the top of the sonic sifter. The signal hits a latex diaphragm on the top of the sieve stack, and causes oscillation. There is also a latex receiver at the base of the sieve stack, and the sieve stack is otherwise sealed, so the latex receiver also oscillates. The air in between the two latex components, therefore moves up an down, carrying the particles with it. BOUND BY OUTDATED TECHNOLOGY AND STANDARDS?

LET OUR APPLICATION SPECIALISTS HELP YOU

FEATURES

- Separation down to 3 microns

- Precise

- Reliable

- Versatile

- Efficient

- Fast

- Meets ASTM and ISO specifications

- No particle attrition

- No screen wear

- Quiet

- Full user support

Sieve stack assembly holds up to (5) sieves or combination of spacers and sieves SPECIFICATIONS

- U.S. standard sieves have stainless steel mesh with a clear acrylic frame. Dimensions: 8.9O.D.x7.6I.D.x1.6H cm (31/2x3x5/8").

- Precision sieves have electroformed nickel mesh with a clear acrylic frame. Dimensions: 8.9O.D.x7.6I.D.x3.2H cm (31/2x3x11/4").

- All sieves meet current sieve specifications of ASTM and ISO.

- Oper. Temperature: –17 to 49°C (1 to 120°F)

- Oper. Humidity: 0–100% RH

- Electrical: 120V, 60Hz, 100W

Quality assurance in manufacturing The unit is virtually maintenance-free, with no need for periodic adjustments or recalibration. Each L3P Sonic Sifter Separator is shipped with a one-year limited warranty, covering parts and workmanship. Prior to shipping, each unit is run for a minimum of four hours to assure optimum performance upon delivery. The Model L3P Sonic Sifter Separator is listed by Underwriters Laboratories, Inc.®

The ATM Model L3P Sonic Sifter Separator is calibrated at the factory to obtain reproducible test results at the "required" power level...a powerful analytical testing tool. Both the power input and the operating time interval can be adjusted for different sieving conditions. SONIC SIFTER INCLUDES COMPLETE SIEVE STACK ASSEMBLY. SIEVES MUST BE SELECTED SEPARATELY

WHITESTONE VA TEL (804) 318-3686 FAX (703) 991-7133 WWW.QCLABEQUIPMENT.COM Copyright 2012: QAQC Lab | Particle Measurement System | All rights reserved. 804-318-3686 | sales@qclabequipment.com