- HOME

- CONSISTOMETER

- ETCHING SYSTEM

- FLUID BED DRYER

- LOSS ON DRYING

- OXYGEN HEAD SPACE

- PARTICLE REDUCTION

- PARTICLE SIZE & SHAPE

- SAMPLE CONTAINERS STAINLESS STEEL

- SAMPLE DIVIDERS

- SAMPLERS ACCESSORIES

- SAMPLERS LIQUIDS

- SAMPLERS POWDERS

- SIEVE ACCESSORIES

- SIEVE CALIBRATION

- SIEVE CALIBRATION BEADS

- SIEVE CALIBRATOR

- SIEVE SHAKERS

- SIEVES ASTM ISO

- SIEVING SONIC

- SURFACE TENSION

- SINAR MOISTURE PROBE

- WATER ACTIVITY

CUSTOMER SERVICE * SALES * TECHNICAL SUPPORT

DELIVERIES WORLDWIDE

PERFORMANCE GUARANTEE

Telephone (804) 318-3686 Toll Free US (866) 244 1578 Fax (703) 991-7133 Hours 8 AM - 6 PM EST INTERNATIONAL & DOMESTIC SALES

www.qclabequipment.com

MANUFACTURING DISTRIBUTION TECHNICAL SERVICES FOR ANALYTICAL INSTRUMENTATION

TELEPHONE (804) 318-3686 TOLL FREE (866) 244-1578

-

AGGREGATE SIZING

AGGREGATE SIZING

-

SIEVER VACUUM

SIEVER VACUUM

-

BALANCES

BALANCES

-

BRIX METERS

BRIX METERS

-

SINAR TECHNOLOGY

SINAR TECHNOLOGY

-

COLOR SHADE ANALYSIS

COLOR SHADE ANALYSIS

-

COLOR SHADE ANALYZER

COLOR SHADE ANALYZER

-

COLOR SHADE INLINE

COLOR SHADE INLINE

-

CONSISTENCY METHOD

CONSISTENCY METHOD

-

SAMPLE CONTAINERS

SAMPLE CONTAINERS

-

PARTICLE SIZE INLINE

PARTICLE SIZE INLINE

-

HOMOGENIZERS

HOMOGENIZERS

-

GERMINATION TESTING

GERMINATION TESTING

-

GRAVEL SAND PARTICLE SIZE

GRAVEL SAND PARTICLE SIZE

-

MOISTURE AGRICULTURE

MOISTURE AGRICULTURE

-

MOISTURE INLINE CONTACT

MOISTURE INLINE CONTACT

-

OVEN ALTERNATIVES

OVEN ALTERNATIVES

-

MOISTURE KARL FISCHER

MOISTURE KARL FISCHER

-

MOISTURE DETERMINATION

MOISTURE DETERMINATION

-

OVENS

OVENS

-

PROTEIN AGGREGATES

PROTEIN AGGREGATES

-

RICE LAB

RICE LAB

-

SAMPLE BLENDERS

SAMPLE BLENDERS

-

SAMPLERS

SAMPLERS

-

SEED COUNTER

SEED COUNTER

-

SIEVING SOFTWARE

SIEVING SOFTWARE

-

TABLET MAKING MACHINE

TABLET MAKING MACHINE

-

VISCOSITY

VISCOSITY

EQUIPMENT FOR QUALITY CONTROL AND R&D PARTICLE SIZE, SHAPE, AND CHARACTERISTIC ANALYSIS One of the most important types of analytical work associated with producing resources and wares with desired properties, is particle size and shape analysis.

Sieving, microscopy, computerized image analysis , laser diffraction, sedimentation, and centrifugation, are some of the analysis methods by which a samples particle characterization may be established. Some of the considerations that come in to play are:

- THE PHYSICAL STATE OF THE SAMPLE ie... liquid, gas, solid, viscous, cohesive, agglomerative, etc...

- THE RELEVANT SIZE RANGE OF THE PARTICLES TO BE ANALYZED

- TIME AND MANPOWER REQUIREMENTS

- COST

For some applications, like pharmaceuticals,

particle size and shape

characteristics may be critical. For example, risks associated with the infusion of particles that exceed the internal diameter of the pulmonary capillaries, can be deadly."

Sieve analysis is popular in many industries, primarily due to the low cost. It is a primary method, ie... one where two principle parameters of length and weight, are directly traceable to international standards, since a sieve can be calibrated using microscopy, and a balance can be calibrated using reference standard weights.

However, sieve analysis has drawbacks, one of which, like laser diffraction, makes the assumption that particles are round. Especially with particles that are flat, or long (plates and rods), how exactly a particle will find its' way through the correct mesh aperture is somewhat uncertain. In fact sieve analysis is almost completely ineffective for long stringy particles.

Laser diffraction suffers from many of the same problems, with the inaccuracy of results on plates and rods, reaching 31% and 70% respectively, in some cases. [1]

Never the less, sieving is required where physical separations are needed, and many industry standards are rooted in sieve analysis, because of cost, and also because it may have been the only technology available at the time the standard was developed. Therefore, the ability of an instrument to be able to correlate to sieve analysis, may be of some utility.

COMPLETE INTERACTIVE SAMPLER CATALOGUE PDF DOWNLOAD

LABORATORY TEST SIEVES

LASER DIFFRACTION PARTICLE ANALYZER

THESE TWO IMAGES OF GROUND COFFEE PARTICLES HELP SHOW THE INHERENT PROBLEM WITH USING A SQUARE APERTURE FOR SIZE DETERMINATION.

PUBLISHED COFFEE INDUSTRY STANDARDS ARE BASED ON SIEVE ANALYSIS, EVEN THOUGH MUCH OF THE INDUSTRY HAS CHANGED TO LASER OR DIGITAL IMAGING.

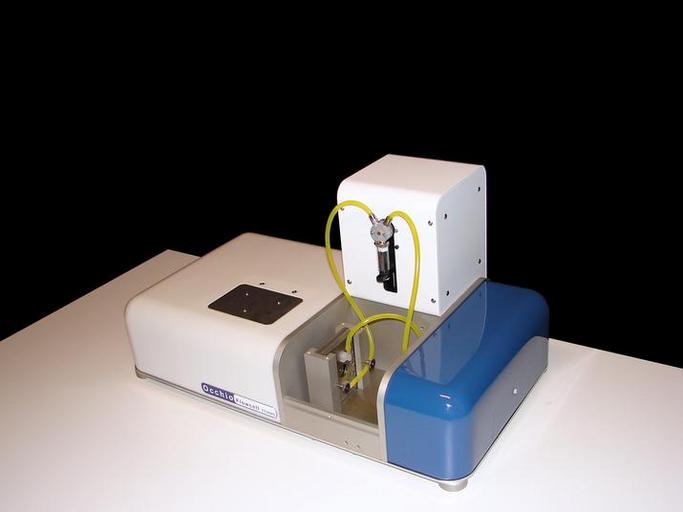

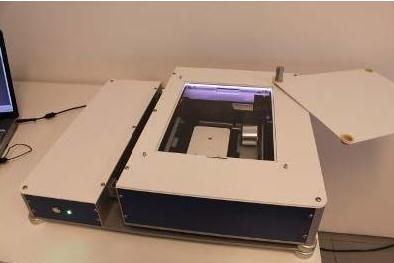

DIGITAL IMAGING MAKES USE OF A PARAMETER CALLED MAXIMUM INSCRIBED DISC, TO PREDICT SIEVE CORRELATION FOR A PARTICLE. ALTHOUGH IT IS THE MOST ACCURATE WAY TO DO THIS, IT STILL DOES NOT ACCOUNT FOR THE DIAGONAL IN A SQUARE APERTURE. DIGITAL IMAGE ANALYZER Recent advances in digital imaging technology, have now made two dimensional particle characterization analysis possible, with both size and shape parameters being employed. Not only can a robust sieve correlation program be developed, but increased accuracy, and the analysis of other useful parameters is now possible.

BLUNTNESS ANALYSIS OF ABRASIVES , SHADE DETECTION, HIGH RESOLUTION REAL TIME ANALYSIS OF PROTEIN AGGREGATES , AND, SIEVE CALIBRATION, ARE JUST SOME OF THE ENCOURAGING APPLICATIONS NOW MADE POSSIBLE BY REAL TIME DIGITAL IMAGING TYPES OF SIEVES

The most common type of sieving medium is constructed of wire mesh. For round, oblong, or other square apertures, the sieve shaker medium is a plate with perforations, made with a punch, or for more exacting applications, electro-formed nickel mesh.

There are also variations in the materials used in manufacture, as well as the tolerances of sieving mediums, although for practical purposes, stainless steel wire mesh is the most widely used and generally accepted.

Aperture Tolerances, wire diameters, (The wire diameter determines the capacity of the sieve (Rate of Sieving ), while the aperture size gives a measure of the particle size.) and general manufacturing parameters, and designations (See left) , are generally defined by geographical standards organizations, industry associations, or prior to industry standardization, sieve manufacturers.

The International Organization for Standardization (ISO) ,and American Society of Testing and Materials (ASTM) are the most prevalent, the latter being the primary agency for U.S. Applications, although many older companies still use Tyler Screen Designations which originated with a company called W.S. Tyler, a long time sieve manufacturer. In the U.S., ASTM Designations are generally used, while ISO Designations are used internationally.

Because the Tyler Sieve Designations are similar, but not equal to to ASTM Designations, it is best to check the millimeter equivalents to make sure everyone is on the same page. It is an altogether too common occurrence, where disputes have risen simply from using the wrong vernacular.

PERFORATED PLATE SIEVES ARE AVAILABLE WITH ROUND HOLES, SQUARE HOLES, OR SLOTS. THEY ARE USED IN SIEVING AGRICULTURAL PRODUCTS, CEREALS, COFFEE, AND OTHER LARGE SIZED COMMODITIES

NEW ISO 4150 BEAN GRADING SIEVES PRECISION ELECTRO-FORMED SIEVES ARE MADE BY A SPECIAL PROCESS, AND ARE USED WHERE TOLERANCE REQUIREMENTS ARE EXTREME. THEY ARE USED FOR PARTICLE SEPARATIONS BELOW 20 MICRONS. WIRE MESH SIEVES ARE THE MOST POPULAR TYPE OF SIEVE FOR PARTICLE SIZING. THEY ARE AVAILABLE IN VARIOUS MATERIALS AND SIZES, AND WITH DIFFERENT TOLERANCES, DEPENDING ON THE ACCURACY REQUIREMENTS SPECIFIED IN THE TEST SODA LIME GLASS MICRO-SPHERES ARE USED TO CALIBRATE BOTH SIEVES, AND LASER DIFFRACTION ANALYZERS. BECAUSE THEY CAN BE USED ONLY ONCE PER TEST, THE COST OF CALIBRATING TEST SIEVES CAN BE EXPENSIVE. DIGITAL IMAGING HAS BEEN USED SUCCESSFULLY FOR THIS TASK.

Sieve Shakers

particle size analysis

OFFICIAL ASTM HAND SIEVING METHOD "The nest of sieves is cradled loosely in a slightly inclined position in the crook of the arm, and tapped at the rate of approximately 120 times per minute with the flat of the hand. After about 30 taps, the sieves are put into a horizontal position, turned through 909 degrees, and given a sharp vertical shape, and a hard tap."

The sieving time depends on a variety of factors, such as the characteristics of the material, sieve size, volume of the charge, relative humidity, and so on, although the rule is that with one additional minute of sieving , if the amount retained on any one sieve changes less than 1%, the endpoint has been reached.

Because sieving by hand is difficult to perform in the first place, and the results are somewhat subjective, different types of sieve shakers are available to separate various sample types.

VIBRATORY

SIEVE SHAKERS

OFFER

EXCELLENT SEPARATION, AND LOW NOISE LEVELS

ROTATING TAPPING

SIEVE SHAKERS

WERE DESIGNED MANY YEARS AGO, TO SIMULATE HAND SIEVING. BECAUSE MANY INDUSTRY STANDARDS WERE DEVELOPED WITH

THIS TYPE OF SIEVE SHAKER, THEY ARE STILL FOUND IN MANY BUSINESSES. THEY ARE KNOWN TO PRODUCE VERY LOUD NOISE, AND ARE NORMALLY KEPT AND OPERATED IN A SOUND PROOF ENCLOSURE

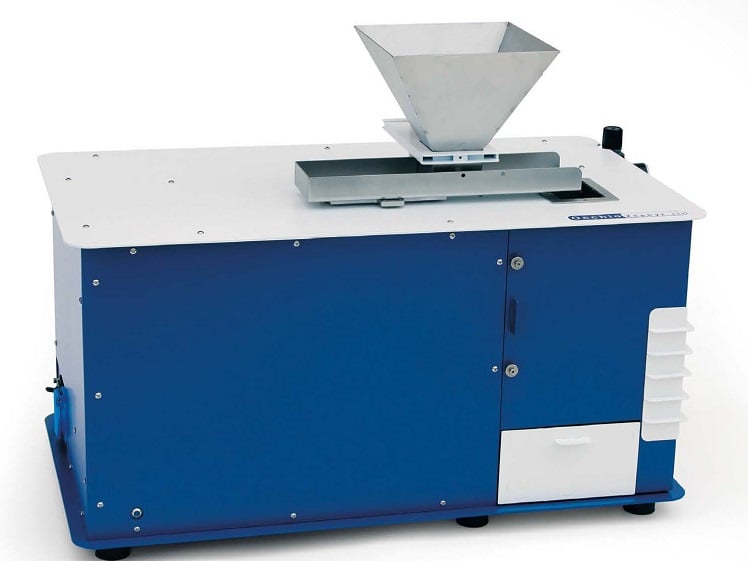

LARGE SIEVE SHAKERS ARE USED FOR SMALL SCALE PROCESSING, AND LARGE SAMPLE BATCHES. 18 INCH SIEVES HAVE ALSO BEEN FOUND TO GIVE RESULTS

EQUIVALENT TO PRECISION ELECTRO FORMED SIEVES

SONIC SIFTERS USE A LOW FREQUENCY AUDIO SIGNAL AND MIRRORED LATEX DIAPHRAGMS, TO PROVIDE VERY EFFICIENT SEPARATIONS, EVEN BELOW 20 MICRONS. CARE MUST BE TAKEN WITH COHESIVE POWDERS

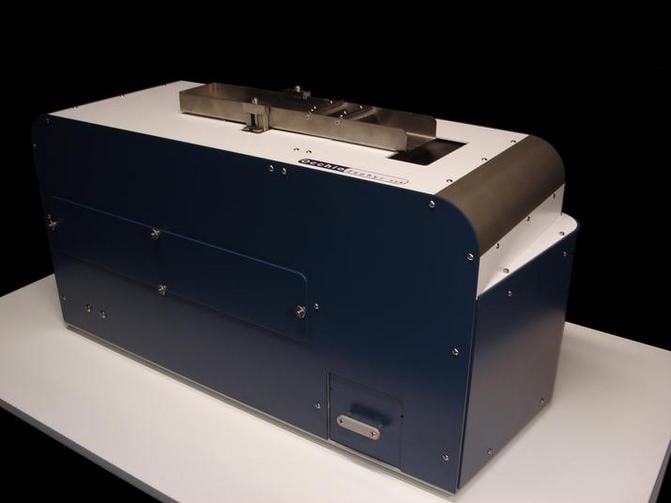

VACUUM SIEVERS USE A ROTATING AIR JET, AND SLIGHT VACUUM, TO PROVIDE EFFECTIVE SEPARATIONS FOR DIFFICULT POWDERS THAT MAY OTHERWISE AGGLOMERATE. 1. Gabas N, Hiquily N, Laguuerie C. Response of Laser Diffraction Particle Sizer to Anisometric Particles. Part Part Syst Charact, 11:121-126, 1994

WHITESTONE VA TEL (804) 318-3686 FAX (703) 991-7133 INFORMATION@QCLABEQUIPMENT.COM WWW.QCLABEQUIPMENT.COM Copyright 2012: QAQC Lab | Particle Measurement System | All rights reserved. 804-318-3686 | sales@qclabequipment.com