- HOME

- CONSISTOMETER

- ETCHING SYSTEM

- FLUID BED DRYER

- LOSS ON DRYING

- OXYGEN HEAD SPACE

- PARTICLE REDUCTION

- PARTICLE SIZE & SHAPE

- SAMPLE CONTAINERS STAINLESS STEEL

- SAMPLE DIVIDERS

- SAMPLERS ACCESSORIES

- SAMPLERS LIQUIDS

- SAMPLERS POWDERS

- SIEVE ACCESSORIES

- SIEVE CALIBRATION

- SIEVE CALIBRATION BEADS

- SIEVE CALIBRATOR

- SIEVE SHAKERS

- SIEVES ASTM ISO

- SIEVING SONIC

- SURFACE TENSION

- SINAR MOISTURE PROBE

- WATER ACTIVITY

www.qclabequipment.com

CUSTOMER SERVICE * SALES * TECHNICAL SUPPORT

DELIVERIES WORLDWIDE

PERFORMANCE GUARANTEE

Telephone (804) 318-3686 Toll Free US (866) 244 1578 Fax (703) 991-7133 Hours 8 AM - 6 PM EST INTERNATIONAL & DOMESTIC SALES

-

AGGREGATE SIZING

AGGREGATE SIZING

-

SIEVER VACUUM

SIEVER VACUUM

-

BALANCES

BALANCES

-

BRIX METERS

BRIX METERS

-

SINAR TECHNOLOGY

SINAR TECHNOLOGY

-

COLOR SHADE ANALYSIS

COLOR SHADE ANALYSIS

-

COLOR SHADE ANALYZER

COLOR SHADE ANALYZER

-

COLOR SHADE INLINE

COLOR SHADE INLINE

-

CONSISTENCY METHOD

CONSISTENCY METHOD

-

SAMPLE CONTAINERS

SAMPLE CONTAINERS

-

PARTICLE SIZE INLINE

PARTICLE SIZE INLINE

-

HOMOGENIZERS

HOMOGENIZERS

-

GERMINATION TESTING

GERMINATION TESTING

-

GRAVEL SAND PARTICLE SIZE

GRAVEL SAND PARTICLE SIZE

-

MOISTURE AGRICULTURE

MOISTURE AGRICULTURE

-

MOISTURE INLINE CONTACT

MOISTURE INLINE CONTACT

-

OVEN ALTERNATIVES

OVEN ALTERNATIVES

-

MOISTURE KARL FISCHER

MOISTURE KARL FISCHER

-

MOISTURE DETERMINATION

MOISTURE DETERMINATION

-

OVENS

OVENS

-

PROTEIN AGGREGATES

PROTEIN AGGREGATES

-

RICE LAB

RICE LAB

-

SAMPLE BLENDERS

SAMPLE BLENDERS

-

SAMPLERS

SAMPLERS

-

SEED COUNTER

SEED COUNTER

-

SIEVING SOFTWARE

SIEVING SOFTWARE

-

TABLET MAKING MACHINE

TABLET MAKING MACHINE

-

VISCOSITY

VISCOSITY

MANUFACTURING DISTRIBUTION TECHNICAL SERVICES FOR ANALYTICAL INSTRUMENTATION

TELEPHONE (804) 318-3686 TOLL FREE (866) 244-1578

EQUIPMENT FOR QUALITY CONTROL AND R&D 500 NANO PARTICLE CHARACTERIZATION SYSTEM FOR SMALL PRECISE AMOUNTS OF FINE POWDERS TO 400 nm

NEW! NANO XY WITH REMOVEABLE FLOWCELL FOR THE ANALYSIS OF PARTICLES IN SUSPENDED IN LIQUID

COMPLETE INTERACTIVE SAMPLER CATALOGUE PDF DOWNLOAD

Contact Us

We will get back to you as soon as possible

Please try again later

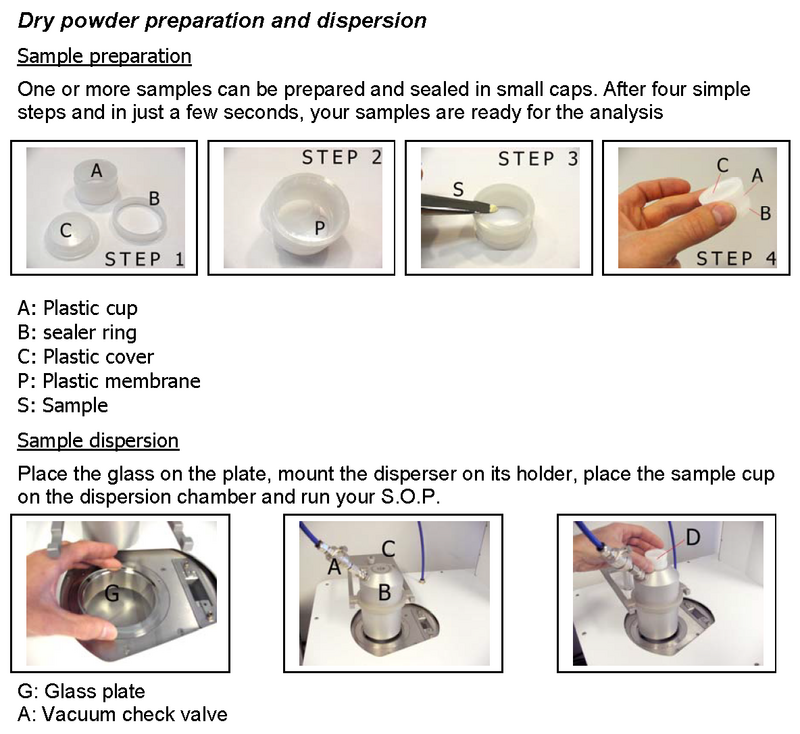

The 500 NANO Analyzer is specifically designed for static, non destructive analysis of low volumes (Down to 1 ml) of very fine powders. The sample is placed in a small cup with a tearable membrane floor. WHAT IS UNIQUE COMPARED TO OTHER DIGITAL IMAGING DEVICES NANO XY POWDER & LIQUID ANALYZER SAMPLE TYPE: VERY FINE POWDERS DRY 400 nm to 3 mm WET 400 nm to 1 mm

SAMPLE TRANSPORT METHOD: SPECIAL NON DESTRUCTIVE VACUUM PUMP AND TEAR ABLE MEMBRANE DISPERSION FOR POWDERS

PURPOSE DESIGNED PUMP WITH LIQUID FLOWCELL FOR PARTICLES IN SUSPENSION AFTER YEARS OF RESEARCH IN OPTICS AND LIGHT, OCCHIO DEVELOPED A SPECIAL MONOCHROMATIC BACK LIGHT TO PROVIDE SUPERIOR PARTICLE DEFINITION. COMPARED TO NORMAL WHITE LIGHT,. ALLOWING FOR THE DETECTION OF PARTICLES BELOW 1 MICRON.

THE BLUE LIGHT SOURCE IS COLLIMATED, AND ACTS LIKE A CALIPER, MEASURING ALL FACETS OF EACH PARTICLE IN HIGH DEFINITION. BROCHURE AND DATA SHEET 500 NANO XY Occhio Digital Imaging Analyzers are uniquely suited for particle size, shape, and distribution analysis, in the range of 200 nm to 3.0 mm. Depending on the size of the particles to be analyzed, what form they are in, ie...liquid or solid, and the volume of the sample, different dispersion techniques are employed relative to the required throughput, to provide optimal conditions for image capture.

A special vacuum pump is then used to tear the membrane, and deposit millions of particles on a glass slide, in just a few seconds. Each analysis can be defined as an SOP, so that frequent tests can be run by several operators, with no need for programming, and the same results everytime.

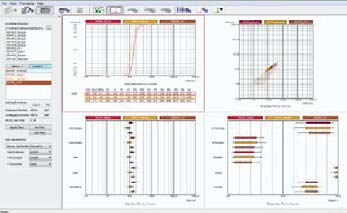

After running an analysis, the comprehensive analytical software package CALLISTO tm creates detailed reports, and provides bimodal, as well as three dimensional graphs, showing shape and size distribution by number, or percentage. The integrity of the powder is maintained, while agglomerates are gently dissociated, providing good orientation, and natural sedimentation on the glass slide. What is unique, compared to other methods, specifically laser diffraction , and sieve analysis , is the ability to detect particle shape, instead of making the practical, but false assumption, that all particles are spherical.

When you have the ability to measure, and quantify, particle shape parameters, particle size takes on a whole new meaning.

REASONS TO TAKE PARTICLE SHAPE IN TO CONSIDERATION WHAT IS UNIQUE WHEN COMPARED TO LASER DIFFRACTION AND SIEVE ANALYSIS 1- PARTICLE SHAPE AFFECTS THE PERFORMANCE ATTRIBUTES OF THE FINISHED PRODUCT

BES

IDES AFFECTING POWDER FLOW AND MIXING PROPERTIES, PARTICLE SHAPE IS CRITICAL IN THE EVALUATION OF MATERIALS LIKE ABRASIVES, WHERE THERE IS REDUCED PERFORMANCE AS THE PARTICLE IS CLOSER TO

BEING SPHERICAL.

NEWLY DEFINE SHAPE PARAMETERS INCLUDE ROUGHNESS, AND BLUNTNESS ANALYSIS IN ABRASIVES, WHERE THE DEVIATION FROM SPHERICITY IS MEASURED, ALONG WITH THE SHAPE OF THE ASPERITIES

CALL FOR AN ONLINE DEMONSTRATION (866) 244-1578

2-SHAPE INFORMATION ALLOWS FOR BETTER CORRELATION TO EXISTING METHODS

MANY INDUSTRIES HAVE THEIR STANDARDS DEFINED BY SIEVE ANALYSIS. SO ALTHOUGH LASER AND DIGITAL IMAGING PROVIDE FOR MORE COMPREHENSIVE ANALYSIS, THEY STILL NEED TO BE ABLE TO CORRELATE TO SIEVE RESULTS.

LEFT-OCCHIO USES THE CONCEPT OF THE MAXIMUM INSCRIBED VIRTUAL DISC, TO MEASURE THE WIDEST PART OF THE PARTICLE, WHICH WOULD INDICATE WHICH SIEVE APERTURE THE PARTICLE WOULD BE RETAINED BY. LASER DIFFRACTION DOES NOT HAVE THIS CAPABILITY.

RIGHT-A PICTURE OF A COFFEE GRIND,SHOWS THE PROBLEM WITH USING SIEVE ANALYSIS TO MEASURE THE SIZE OF NON SPHERICAL PARTICLES 3- PARTICLE SHAPE ANALYSIS ALLOWS FOR NEW OPPORTUNITIES IN R&D, AND QUALITY CONTROL

WHITESTONE VA TEL (804) 318-3686 FAX (703) 991-7133 INFORMATION@QCLABEQUIPMENT.COM WWW.QCLABEQUIPMENT.COM Copyright 2012: QAQC Lab | Particle Measurement System | All rights reserved. 804-318-3686 | sales@qclabequipment.com