- HOME

- CONSISTOMETER

- ETCHING SYSTEM

- FLUID BED DRYER

- LOSS ON DRYING

- OXYGEN HEAD SPACE

- PARTICLE REDUCTION

- PARTICLE SIZE & SHAPE

- SAMPLE CONTAINERS STAINLESS STEEL

- SAMPLE DIVIDERS

- SAMPLERS ACCESSORIES

- SAMPLERS LIQUIDS

- SAMPLERS POWDERS

- SIEVE ACCESSORIES

- SIEVE CALIBRATION

- SIEVE CALIBRATION BEADS

- SIEVE CALIBRATOR

- SIEVE SHAKERS

- SIEVES ASTM ISO

- SIEVING SONIC

- SURFACE TENSION

- SINAR MOISTURE PROBE

- WATER ACTIVITY

www.qclabequipment.com

CUSTOMER SERVICE * SALES * TECHNICAL SUPPORT

DELIVERIES WORLDWIDE

PERFORMANCE GUARANTEE

Telephone (804) 318-3686 Toll Free US (866) 244 1578 Fax (703) 991-7133 Hours 8 AM - 6 PM EST INTERNATIONAL & DOMESTIC SALES

-

AGGREGATE SIZING

AGGREGATE SIZING

-

SIEVER VACUUM

SIEVER VACUUM

-

BALANCES

BALANCES

-

BRIX METERS

BRIX METERS

-

SINAR TECHNOLOGY

SINAR TECHNOLOGY

-

COLOR SHADE ANALYSIS

COLOR SHADE ANALYSIS

-

COLOR SHADE ANALYZER

COLOR SHADE ANALYZER

-

COLOR SHADE INLINE

COLOR SHADE INLINE

-

CONSISTENCY METHOD

CONSISTENCY METHOD

-

SAMPLE CONTAINERS

SAMPLE CONTAINERS

-

PARTICLE SIZE INLINE

PARTICLE SIZE INLINE

-

HOMOGENIZERS

HOMOGENIZERS

-

GERMINATION TESTING

GERMINATION TESTING

-

GRAVEL SAND PARTICLE SIZE

GRAVEL SAND PARTICLE SIZE

-

MOISTURE AGRICULTURE

MOISTURE AGRICULTURE

-

MOISTURE INLINE CONTACT

MOISTURE INLINE CONTACT

-

OVEN ALTERNATIVES

OVEN ALTERNATIVES

-

MOISTURE KARL FISCHER

MOISTURE KARL FISCHER

-

MOISTURE DETERMINATION

MOISTURE DETERMINATION

-

OVENS

OVENS

-

PROTEIN AGGREGATES

PROTEIN AGGREGATES

-

RICE LAB

RICE LAB

-

SAMPLE BLENDERS

SAMPLE BLENDERS

-

SAMPLERS

SAMPLERS

-

SEED COUNTER

SEED COUNTER

-

SIEVING SOFTWARE

SIEVING SOFTWARE

-

TABLET MAKING MACHINE

TABLET MAKING MACHINE

-

VISCOSITY

VISCOSITY

MANUFACTURING DISTRIBUTION TECHNICAL SERVICES FOR ANALYTICAL INSTRUMENTATION

TELEPHONE (804) 318-3686 TOLL FREE (866) 244-1578

EQUIPMENT FOR QUALITY CONTROL AND R&D QAQC LAB UD MASTER SAMPLER (Meets FDA Guidelines)

STORE SEARCH

COMPLETE INTERACTIVE SAMPLER CATALOGUE PDF DOWNLOAD

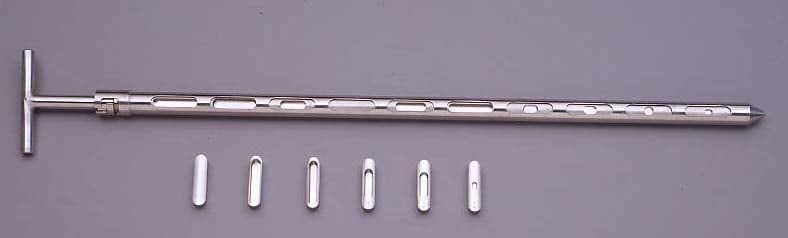

The patented U-D Master is designed for multilevel, low volume sampling in the pharmaceutical industry.

It is ideal for use with free flowing powders. By simply changing the sample inserts (cells), different volumes can be sampled.

Contact Us

We will get back to you as soon as possible

Please try again later

• Manufactured from 316 stainless steel • Satin polish (Ra< 1microns) • Take Multiple Samples from the same Point • Range of sampler lengths • Change the sample volume by changing the insert • Special finishes and materials of construction available on request. More than one sample can be taken from the same sampling point (See double or triple styles).

Sample Inserts are stamped with their volume for easy identification Sample Inserts are available in a range of sizes from 0.1ml to 4.0ml, plus blank inserts

Samples are taken from powder blends to test for content uniformity before further processing, such as tableting or encapsulation. Integrity of the sampling technique is critical in order to ensure accuracy of the test results. Unit-dose sampling has been proven to improve the accuracy of the content uniformity results. However, there is still room for sampling error in unit-dose sampling if the samples are submitted to the laboratory in powder form.

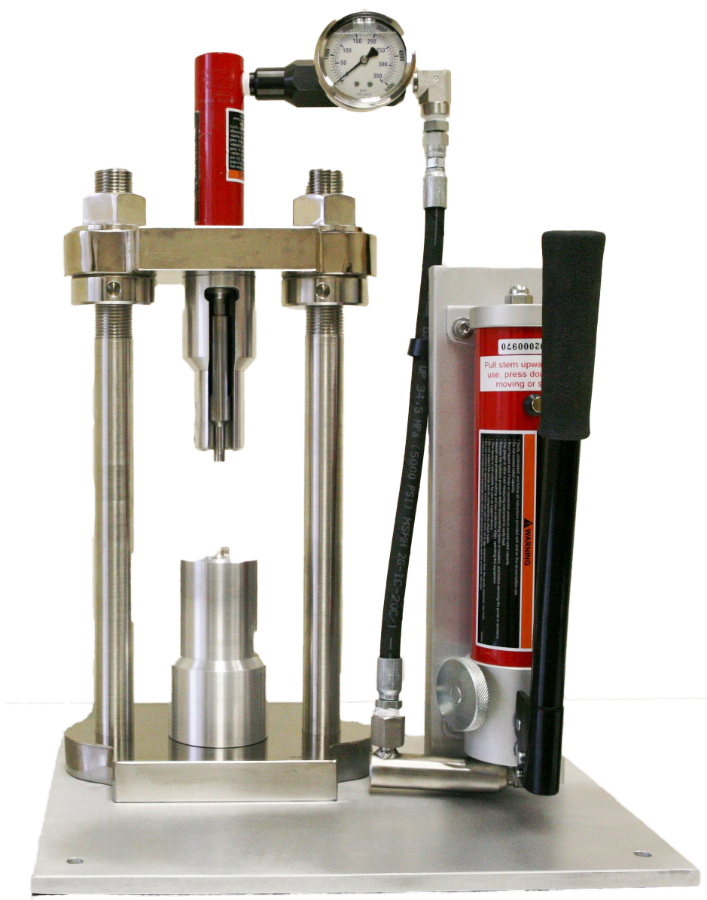

This New Unit-dose Powder Sampling Technique further reduces the sampling error by combining unit-dose sampling with compaction of the powder sample into a real tablet in the sample die itself.

Compaction of the powder samples into tablets may reduce the sampling error because the samples are in compacted form and handling of the loose powder samples by the operator or the analyst is completely eliminated. Several major pharmaceutical companies have already successfully utilized this technique in situations where the blend samples were failing the content uniformity test while the tablets compressed from the same blends were passing the test. This technique is strongly recommended especially when you have a low dose directly compressible “New Unit-Dose Powder Sampling Technique.” This machine is used to compact the powder sample into a tablet in the sampling die itself by hydraulic pressure. A 3,000 lb capacity pressure gauge is provided. No electricity or compressed air is required.

The machine is compact (8”D x 16”W x 16”H) and portable (30 lb) and works with standard tablet tooling. QAQC Lab offers, for the sake of customers’ convenience, six different types and sizes of standardized punches, covering the entire sample size range of 0.1cc to 3.0cc.

A table showing the sample size and corresponding punch type and size is given below:

WHITESTONE VA TEL (804) 318-3686 FAX (703) 991-7133 INFORMATION@QCLABEQUIPMENT.COM WWW.QCLABEQUIPMENT.COM Copyright 2012: QAQC Lab | Particle Measurement System | All rights reserved. 804-318-3686 | sales@qclabequipment.com