- HOME

- CONSISTOMETER

- ETCHING SYSTEM

- FLUID BED DRYER

- LOSS ON DRYING

- OXYGEN HEAD SPACE

- PARTICLE REDUCTION

- PARTICLE SIZE & SHAPE

- SAMPLE CONTAINERS STAINLESS STEEL

- SAMPLE DIVIDERS

- SAMPLERS ACCESSORIES

- SAMPLERS LIQUIDS

- SAMPLERS POWDERS

- SIEVE ACCESSORIES

- SIEVE CALIBRATION

- SIEVE CALIBRATION BEADS

- SIEVE CALIBRATOR

- SIEVE SHAKERS

- SIEVES ASTM ISO

- SIEVING SONIC

- SURFACE TENSION

- SINAR MOISTURE PROBE

- WATER ACTIVITY

www.qclabequipment.com

CUSTOMER SERVICE * SALES * TECHNICAL SUPPORT

DELIVERIES WORLDWIDE

PERFORMANCE GUARANTEE

Telephone (804) 318-3686 Toll Free US (866) 244 1578 Fax (703) 991-7133 Hours 8 AM - 6 PM EST INTERNATIONAL & DOMESTIC SALES

-

AGGREGATE SIZING

AGGREGATE SIZING

-

SIEVER VACUUM

SIEVER VACUUM

-

BALANCES

BALANCES

-

BRIX METERS

BRIX METERS

-

SINAR TECHNOLOGY

SINAR TECHNOLOGY

-

COLOR SHADE ANALYSIS

COLOR SHADE ANALYSIS

-

COLOR SHADE ANALYZER

COLOR SHADE ANALYZER

-

COLOR SHADE INLINE

COLOR SHADE INLINE

-

CONSISTENCY METHOD

CONSISTENCY METHOD

-

SAMPLE CONTAINERS

SAMPLE CONTAINERS

-

PARTICLE SIZE INLINE

PARTICLE SIZE INLINE

-

HOMOGENIZERS

HOMOGENIZERS

-

GERMINATION TESTING

GERMINATION TESTING

-

GRAVEL SAND PARTICLE SIZE

GRAVEL SAND PARTICLE SIZE

-

MOISTURE AGRICULTURE

MOISTURE AGRICULTURE

-

MOISTURE INLINE CONTACT

MOISTURE INLINE CONTACT

-

OVEN ALTERNATIVES

OVEN ALTERNATIVES

-

MOISTURE KARL FISCHER

MOISTURE KARL FISCHER

-

MOISTURE DETERMINATION

MOISTURE DETERMINATION

-

OVENS

OVENS

-

PROTEIN AGGREGATES

PROTEIN AGGREGATES

-

RICE LAB

RICE LAB

-

SAMPLE BLENDERS

SAMPLE BLENDERS

-

SAMPLERS

SAMPLERS

-

SEED COUNTER

SEED COUNTER

-

SIEVING SOFTWARE

SIEVING SOFTWARE

-

TABLET MAKING MACHINE

TABLET MAKING MACHINE

-

VISCOSITY

VISCOSITY

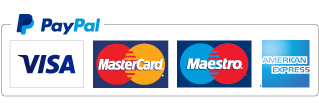

EQUIPMENT FOR QUALITY CONTROL AND R&D PNEUMATIC INLINE POWDER SAMPLER JAM PROOF

STORE SEARCH "The general consensus is that only sampling from a bulk powder while it is in motion can yield the desired representative sample." BROCHURE

Contact Us

We will get back to you as soon as possible

Please try again later

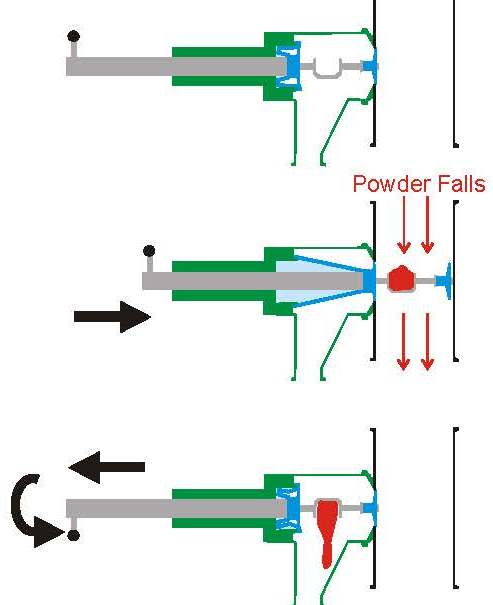

INLINE POWDER SAMPLER AUTOMATIC OPERATION PIPE DIAMETER 100mm to 300mm 675 FG (xxx m/a) CHOOSING THE RIGHT SIZE The Pneumatic Inline Powder Sampler is specially designed and engineered so that powder is kept out of the bearings by a special flexible membrane - this means the sampler will not jam

The sample is collected in a cup and so is not physically altered by the sampling process When the sampling cup is retracted, the full bore of the downpipe is available for powder flow

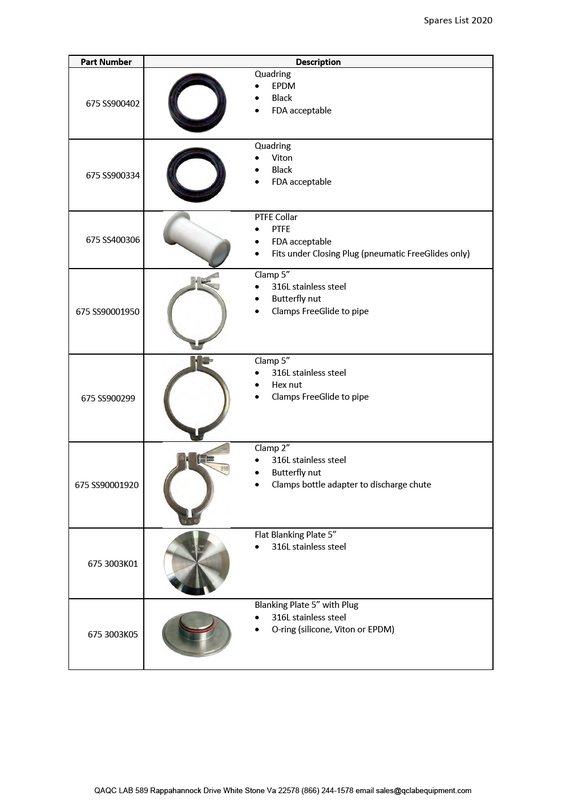

Made from FDA acceptable materials and is easy to strip down for cleaning MATERIALS OF CONSTRUCTION

Contact parts: - 316 stainless steel - PTFE - Silicone rubber, Viton or EPDM - Other materials on request

Non contact parts: - 304 grade stainless steel - Other materials as required.

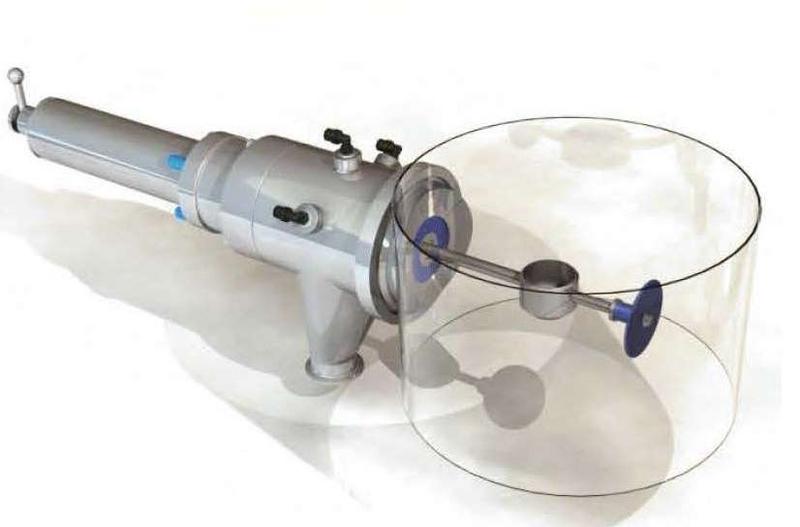

OPERATION

Resting

When the sampler is not in use the full bore of the downpipe is available for powder flow.

Sampling

The sampling cup is extended into the downpipe to catch the product as it falls.

Discharging

The sampling cup is then retracted and inverted. The powder sample falls down the discharge chute to where it is collected DOWNLOADS BROCHURE FREEGLIDE INLINE POWDER SAMPLER

The blanking plate is a 316 SS Plate that fits in to the front boss, while the sampler is being serviced. Two styles are available The automatic sampler uses pneumatics to extend and retract the cup and to rotate it. Electrical sensors are used to monitor the position of the automatic sampler . SAMPLE MANUAL FOR AUTOMATIC FREEGLIDE

675 FG1000A 100 mm DIAMETER PIPE AUTOMATIC SAMPLER

675 FG1500A 150 mm DIAMETER PIPE AUTOMATIC SAMPLER

675 FG2000A 200 mm DIAMETER PIPE AUTOMATIC SAMPLER

675 FG3000A 300 mm DIAMETER PIPE AUTOMATIC SAMPLER

Contact Us

We will get back to you as soon as possible

Please try again later

Recommended maintenance

In order to keep the sampler in good working order, regular maintenance is required, and this should be recorded and kept as a record.

All maintenance personnel who carry out the maintenance on the sampler should be fully qualified.

Recommended weekly maintenance

Visually inspect the Diaphragm for wear* Visually inspect the Closing Plug for wear* Visually inspect the Quadrings for wear* Inspect filters for damage Confirm that there is an earthing route from the cup to the Tee Piece (see section 5.3) Confirm that there is an earthing route from the Tee Piece to the downpipe (see section 5.4) Visually check that the sampler is making a good seal with the inside face of the product chute when in the extended and retracted positions.

* Polymer components must be viewed as consumable parts and replaced at the first signs of wear.

Lubrication schedule There are no components on this sampler assembly which require lubrication.

5.3 Earthing (Grounding) Check – Inside Sampler Ensure that the resistance between the cup and the Tee Piece is less than 1 Ohm. The FreeGlide is fitted with phosphor bronze bearings; these provide a constant metal to metal earthing path through the equipment. There is no adjustment possible by the the customer.

If the resistance is greater than 1 Ohm, then the inner workings of the sampler are electrically isolated. The device must not be reinstalled until it has been properly investigated.

Earthing (Grounding) Check – to surrounding equipment Ensure that the resistance between the Tee Piece and the Downpipe (i.e. surrounding equipment) is less than 1 Ohm.

WHITESTONE VA TEL (804) 318-3686 FAX (703) 991-7133 INFORMATION@QCLABEQUIPMENT.COM WWW.QCLABEQUIPMENT.COM Copyright 2012: QAQC Lab | Particle Measurement System | All rights reserved. 804-318-3686 | sales@qclabequipment.com